Transformation from γ to α

Purpose: Learn to perform diffusion simulation at constant temperature where a g → a transformation happens in Fe-C alloy. Learn to select entered phase(s) in each region.

Module: PanDiffusion

Thermodynamic and Mobility Database: Fe-Si-C.tdb

Batch file: Example_#4.10.pbfx

Calculation Procedures:

-

Create a workspace and select the PanDiffusion module following Pandat User's Guide: Workspace;

-

Load Fe-Si-C.tdb following the procedure in Pandat User's Guide: Load Database and select elements Fe and C.

-

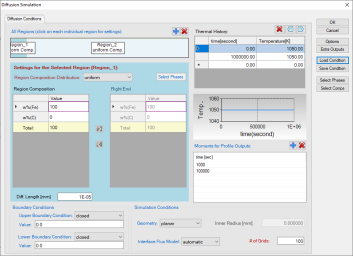

Click on the menu "PanDiffusion → Diffusion Simulation" and set up the calculation condition as shown in Figure 1;

-

Click on Region_1 and set the composition as 100Fe-0C (wt%), and select Bcc as the entered phase in “Select Phases” of “Settings for the Selected Region [Region_1]”. In Region_1, set the Diff. Length as 1E-5 mm. Click on Region_2 and set the composition as 99.85Fe-0.15C (wt%) and select Fcc as the entered phase in “Select Phases” of “Settings for the Selected Region [Region_2]”. In Region_2, set the Diff. Length as 2 mm;

-

The Thermal History is at 1050 K for 1E6 seconds;

-

The total number of grids (# of Grids) is 100;

-

In the settings shown in Figure 1, composition profiles at the initial and final stages, as well as at 1E3 seconds and 1E5 seconds, will be outputted. Click OK to perform calculations.

Post Calculation Operation:

-

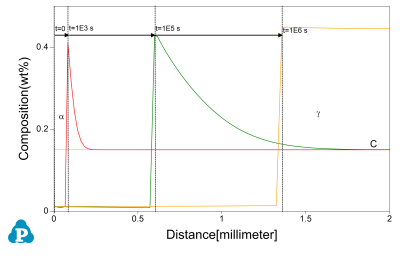

Enlarge the composition range between 0 and 0.5 (wt%) to clearly display Carbon composition.The calculated plot is show in Figure 2Change graph appearance and add text following the procedure in Pandat User's Guide: Property.

Information obtained from this calculation:

-

Observe composition profiles of C and interface movement from a to g which indicates the g → a phase transformation.